1985-1993

2000

2003-2006

2008-2009

2015-2020

My 1968 VW Type 2 Bus Conversion

VW Type 2 930 3.3 Turbo Engine Swap

by Harold Williams

July 2015

2014 - 2015 Projects: 930 3.3 turbo engine swap

I've been running a '86 911 motor & 5 speed transmission (7:31 r&p) for the past eight years, and have been happy with the results. At sea level the motor was putting out approximately 240-250 c.h.p. Then we moved to an elevation of 7,000 ft. Horsepower loss is around 25%, too much for me to bear.

I considered adding a turbo to the 3.2 motor. My choice would be to retain the stock compression ratio and run a low boost, or to replace the p&c's with a lower compression ratio set in order to use a higher boost. I would also need to buy all the ancillary parts for the conversion. I felt buying a complete turbo motor would be less expensive. I choose the '75-'77 930 3.0 turbo motor, which puts out approximately 260 c.h.p. This motor was designed to run without an intercooler, which would make the installation easier. I was surprised to find that the motor I purchased came with a rare Andial/Garrertson intercooler. This gave me the option of adding it if needed. After receiving the motor I started inspecting the parts. It became clear after further disassembly that pretty much everything would need to be refurbished, rebuilt or replaced. I started sending parts out to the various machine shops. The short block and p&c's were so badly worn and out of spec they were unusable. Parts Heaven, the Porsche Dismantler I purchased the motor from stepped up to the plate and offered either a full refund or to replace the unusable parts with 3.3 turbo parts. As these motors are getting harder find, I opted for the replacement parts. The new configuration would consist of the 3.3 short block, 3.3 pistons & cylinder, while retaining the 3.0 heads and intake system. I switched to electronic ignition since the 3.0 distributor isn't interchangeable with the 3.3.

While I'm waiting for the parts to get machined I moved onto prepping the bus.

Suspension: Eibach 7" long x 150 lb. coilover main springs were added to the rear Wevo/Ohlins adjustable shocks. The springs help with the increased motor weight and turbo squat. The 27mm rear torsion bars were retained.

Brakes: For better stopping power, the front calipers were up graded to the larger Wilwood Forged Superlite calipers (#120-11137 & 38). The 912 solid rotors were replaced with 911 slotted/vented rotors.

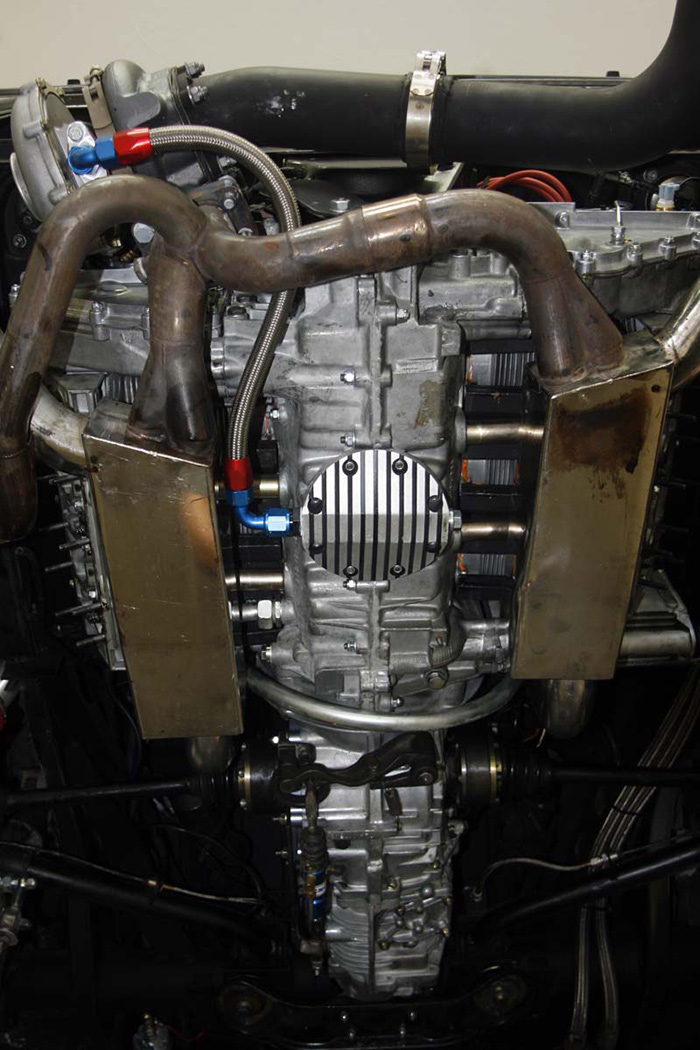

Transaxle: The '84 aluminum case 915 5 speed transaxle was sent to Wevo for a complete rebuild and a few up grades to handle the increased power. A Wevo bearing retainer plate and side cover replace the stock pieces. The 7:31 r&p was replaced with a 8:31 r&p which is a better match to the turbo motor. Top speed is estimated to be around 130-140 mph. It will never see those speeds with me driving.

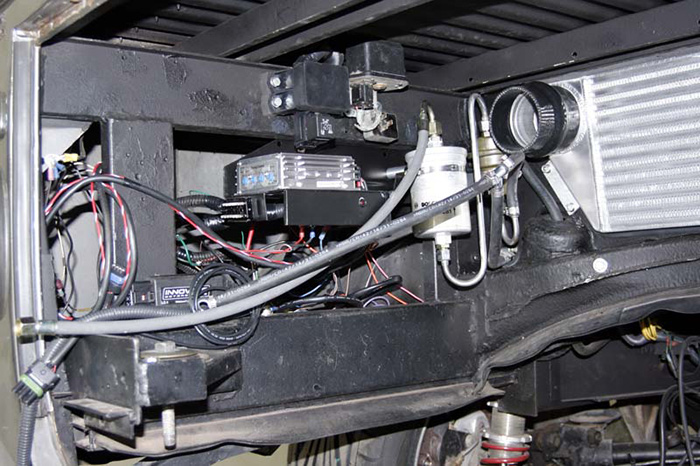

Engine bay prep: The 14 pin plug was reconfigured to match the engine plug. The XDI cpu is mounted to the stock electrical panel. A Painless 8 fuse panel sits above.

Fuel system: The fuel system was changed out to match the requirements of the 930 CIS system. This is a continuous circulating system requiring 97 psi fuel pressure. To increase the fuel flow I machined a larger fuel tank outlet, originally 1/8" i.d., now 3/8" i.d. The gas tank no longer has fuel screen so a 100 micron fuel filter is used between the tank and fuel pump. A single Bosch Motorsport 993-620-104-80 044 fuel pump is used to provide the adequate fuel pressure. The pump is mounted on the left chassis rail in order to use the stock 930 fuel line that runs from the pump to the accumulator. The fuel filter & accumulator are also located on the left side of the engine bay. A oil catch can/breather vent was added on the right side. A fuel return line had previously been added to the gas tank.

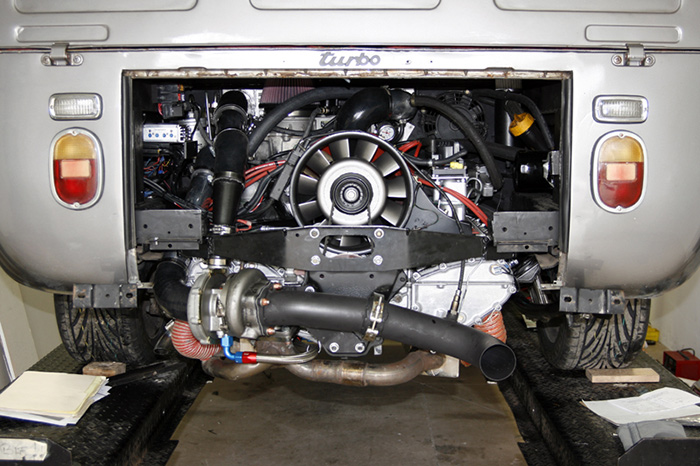

With the increase in displacement and power I choose to add the 3.0 intercooler mounted in the stock location. Though it cleared, the air flow was pretty restricted. I felt a better location would be in the firewall/divider panel in front of the motor which would provide better air flow. Bell Intercooler made the intercooler to my dimensions and engine specs. 2 Spal pusher fans are mounted to the back of the intercooler, and a third Spal puller fan was mounted to the right of the intercooler. The fans are connected to a fan temperature sensor that comes on when the oil temp reaches 180 degrees. The stock intake pipe that goes from the turbo to the air meter housing was replaced using 2.5" diameter silicone connectors and aluminum tubing to clear the motor mount. I modified the original 3.0 pressure line and added 3.0" diameter silicone couplers & aluminum tubing that go to the inlet side of the intercooler. The line from the "out" side of the intercooler to the throttle body also uses 3.0" diameter silicone connectors and aluminum tubing. Ports were added to the aluminum tube for the warm up valve, diverter valve and waste gate lines.

The motor: The stock 3.3 piston & cylinders are used with 7.0 compression. Upgrades include ARP rod bolts, head studs, and a 964 oil pump. The 3.0 turbo heads were ported to 40mm intake & 38mm exhaust and polished, with match porting to the aluminum injector blocks and 3.0 turbo manifold by Turbo Kraft. The stock CIS system was retained with the fuel head & warm up regulator rebuilt to match the new motor specs. Bosch 009 injectors replace the stock ones. The stock cams were re-ground by Elgin Cams to their Sport C2 turbo grind. For the ignition, I used Electromotive XDI electronic ignition, Magnacor wires, Bosch w3cs plugs, The stock exhaust was replaced with Borla headers with heat, and a Tial 46mm wastegate. I made the 3" diameter exhaust pipe in 2 sections so I could insert a baffle. The baffle will get wrapped with some amount of stainless steel wool to reduce the noise. For now I'm using the stock 3DLZ turbocharger. The scavenge pump and associated oil lines were replaced with a gravity feed return line that runs from the bottom of the turbo to a custom sump plate I machined. Fresh air block off plates replace the stock ones. 2 inline blowers will be added to provide heat to the cabin. The motor is mating up to a '84 915 tans, so a 9 bolt 225mm flywheel and Sachs sport clutch was also used.

7/15/15: The motor was fired up and run for 20 minutes with break in oil. The next day the oil was drained, rocker arms adjusted and the heads re torqued. Unfortunately that's when I discovered 2 pulled head studs. My current plan is to strip the motor down, deal with the head studs and have it up by fall. Once it's up and running again I will up date the page with photos and a video.

9/2015

Unfortunately having the intercooler mounted in the bulkhead didn’t let enough air pass through and around the intercooler to cool the motor. I removed the intercooler and 3 6” fans and installed 3 Spal 10” pull fans (3300 c.f.m.) in their place, as well as adding 2 scoops (one with a double inlet) under the chassis with 3” diameter hoses bringing air up in front of the fans. The 3rd hose comes up to the top of the i/c. I picked up a 964 intercooler and mounted it in the stock location. The 3.0 intake & throttle body were replaced with a 3.3 intake (ported to 40mm) and stock throttle body. The 3DLZ turbo was replaced with a K27-7200. I also installed in/out intercooler sensors to monitor the intercooler temperatures. The stock engine lid was replaced with a louvered lid I’ve been carrying around for the past 20 years. I also cut a section of the lid out behind the license plate .

I also had to lower the exhaust pipe below the bumper to get some air flow.

The 3 pc Fuchs wheels were re-configured to 9x17 rears with 245/45/17’s and 8x16 fronts with 225/50/16’s Toyo R1R tires.

3/2016: The wrap up.

Dashboard: I added a few more gauges, a volt meter & clock in the radio opening, and a intercooler in/out air temperature where the ashtray use to reside.

Motor mods: I made a 1 piece exhaust pipe with twin 3” outlets. I went with twin outlets so I could install short baffles wrapped in stainless steel wool to quiet the exhaust down without adding much/ if any back pressure.

Engine bay: The fuse panel was re-configured to operate relays for the 1-10” Spal fan, the heater blower motor and the fuel pump. Running the fan and fuel pump caused the fuse panel circuit breaker to trip after about 20 minutes of run time. A 911 engine bay heater/blower motor was added to provide cabin heat. A second 3 speed blower will also be added to the front of the chassis.

Clutch: After trying a few different sized hydraulic master cylinders and not being happy with the way any of them felt, I converted back to a clutch cable.

Suspension: Front camber is set at -.6 and front toe set to 0. Rear camber is -1.1 and 0 rear toe.

Wheels & tires: The rear tires were replaced with a lower profile Toyo R1R 245/40/17. The 8”x16” front wheels with the 225/45/16’s were flush with the outer fender causing the tire to hit the fender lip when I hit a bump. This was fixed by flattening the fender lip.

3/2021

K27-7006 turbo up grade: rebuild/upgrade billet compressor wheel, upgrade #9 metric turbine housing, new turbine wheel & shaft. This gives a better low/mid range power.

Overview |

Porsche Engine Conversion |

Front & Rear Disc Brake Conversion

Hydraulic Clutch Conversion |

Fuchs wheel conversion

Rack & Pinion Conversion |

Porsche 935 front suspension conversion |

RC10 VW Bus

© 2008 - 2026 Harold Williams