1985-1993

2000

2003-2006

2008-2009

2015-2020

My 1968 VW Type 2 Bus Conversion

VW Type 2 Bus Hydraulic Clutch Conversion

by Harold Williams

February 2011

The images and text on this page can be used for non-commerical purposes only.

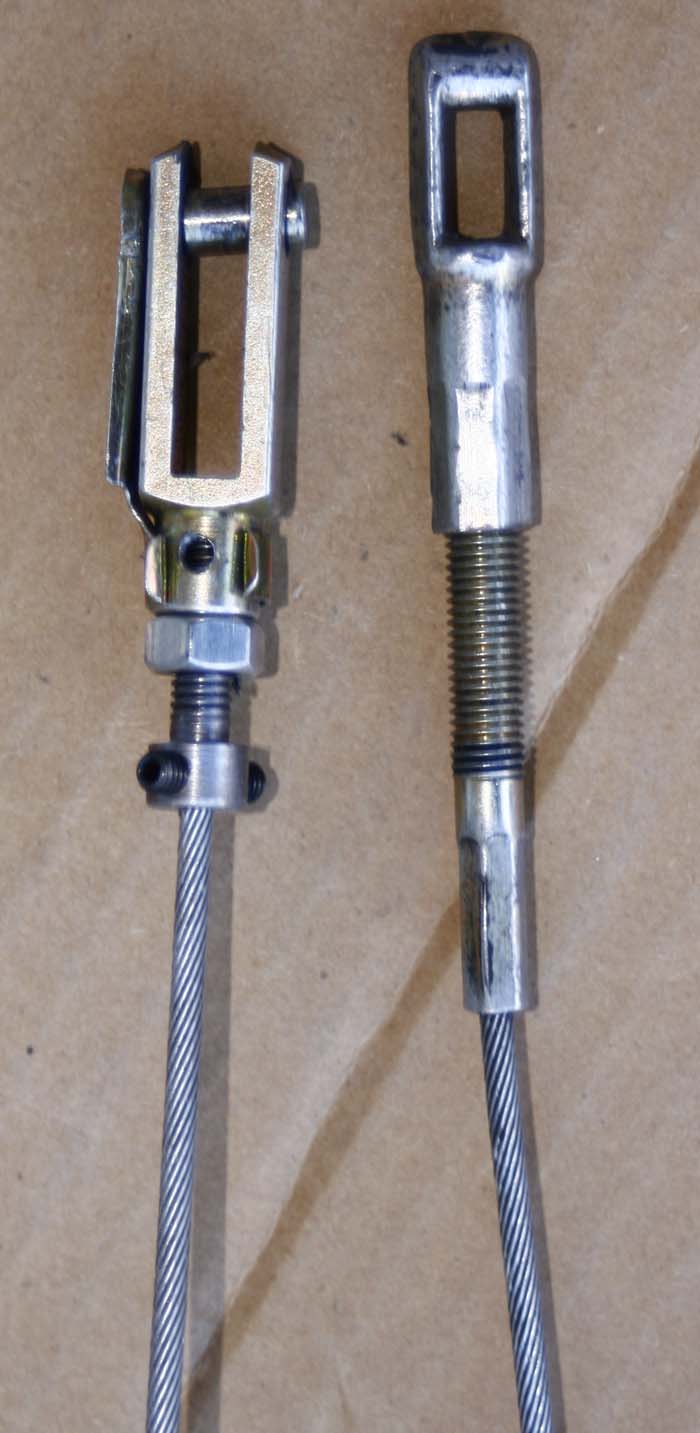

After the 911 motor & trans were installed in my '68 crewcab, one of the next issues was a clutch cable. I couldn't find a cable long enough so I made one. This consisted of using a Porsche boden tube #930 423 401 05 and V.W. cable #211 721 335+e to '71. The pedal end of the V.W cable needs to be cut off to be able to slide into the boden tube. Another end was made and is held in place with 2 set screws. A Porsche clutch end was drilled & tapped to 7mm and the V.W. cable end screws in at the transmission end.

A recurring problem was that the boden cable would get a kink after a short time. This caused the clutch pedal to get significantly stiffer. Also the clutch kept going out of adjustment. I decided to switch to a hydraulic clutch. I went with the CNC master cylinder/slave cylinder kit, and the hydraulic clutch line kit.

-

modified clutch cable -

clutch master cylinder -

clutch slave cylinder (side view) -

steel slave cylinder bracket -

clutch slave cylinder (bottom view)

I welded a small tab onto the bottom of the clutch pedal and as well as an "L" bracket to the frame to mount the master cylinder. At the transmission, I made a bracket to bolt to the side of the transmission and support the slave cylinder. I made a clutch end then drilled and tapped it to screw onto the 5/16" slave cylinder rod. The clutch hydraulic line runs through clutch cable tube. The clutch is adjusted by tightening the nut on the front slave cylinder rod. Since the master cylinder is so close to the floor I drilled a 1-1/2" diameter hole in the floor above the master cylinder so I can fill it. A better alternative would have been a remote reservoir.

To bleed the system I used a small oil can with a hand pump. I

took the top off and rubber gasket out of the master cylinder. A

small hose was used from the can to the bleed screw on the slave

cylinder and brake fluid was pumped through. There was a small

catch can under the master cylinder to catch the fluid as it

overflowed. When there were no more air bubbles I removed some fluid

from the reservoir and installed the rubber seal and cap. The master

cylinder was pre-loaded to achieve about 1" of play at the pedal.

To bleed the system I used a small oil can with a hand pump. I

took the top off and rubber gasket out of the master cylinder. A

small hose was used from the can to the bleed screw on the slave

cylinder and brake fluid was pumped through. There was a small

catch can under the master cylinder to catch the fluid as it

overflowed. When there were no more air bubbles I removed some fluid

from the reservoir and installed the rubber seal and cap. The master

cylinder was pre-loaded to achieve about 1" of play at the pedal.

Overview |

Porsche Engine Conversion |

Front & Rear Disc Brake Conversion

Hydraulic Clutch Conversion |

Fuchs wheel conversion

Rack & Pinion Conversion |

Porsche 935 front suspension conversion |

RC10 VW Bus

© 2008 - 2026 Harold Williams